Abstract

We introduce an open-source toolkit for rapidly prototyping haptic harnesses via an integrated hardware-software workflow. The toolkit merges modular, 3-D printed components, magnetic connectors, and EVA-foam backings with an intuitive parametric software interface that automatically generates fabrication and assembly files. This design removes traditional CAD barriers, allowing researchers and designers to focus on haptic experience rather than mechanical design constraints. We evaluated the system through three complementary studies validating the hardware and software pipelines. First, a hardware evaluation conducted during an inclusive design workshop (n=18) demonstrated usability scores confirming accessibility across participants with diverse design experience. Second, a software usability study with haptics researchers (n=12) identified key interface refinements that guided version 2 improvements. Finally, an end-to-end workflow validation with experienced haptic researchers (n=8) assessed the complete design-to-deployment process. Researchers made custom harnesses in about 26 minutes, with 87.5% reporting accurate actuator placement and faster iteration than traditional CAD-based methods. Across studies, the integrated system achieved a SUS score exceeding industry usability benchmarks. By combining accessible fabrication, streamlined software, and open-source dissemination, this toolkit lowers the entry barrier for haptic hardware development. It enables rapid, repeatable, and customizable design of wearable haptic interfaces, empowering broader participation in embodied interaction research.

Motivation

Wearable haptic devices have immense potential in virtual reality, motor skill rehabilitation, and assistive technologies. However, developing these devices is often slow, expensive, and complex. Researchers and designers face significant challenges in creating robust, customizable harnesses that are comfortable, secure, and can adapt to diverse body sizes and shapes.

This fabrication process is typically labor-intensive and requires specialized expertise in complex CAD software. Our motivation was to lower this significant barrier to entry. We wanted to create an open-source, cost-effective toolkit to empower a broader community of researchers and designers to rapidly prototype and iterate on their haptic ideas, focusing on the experience rather than the complex mechanical design.

Process

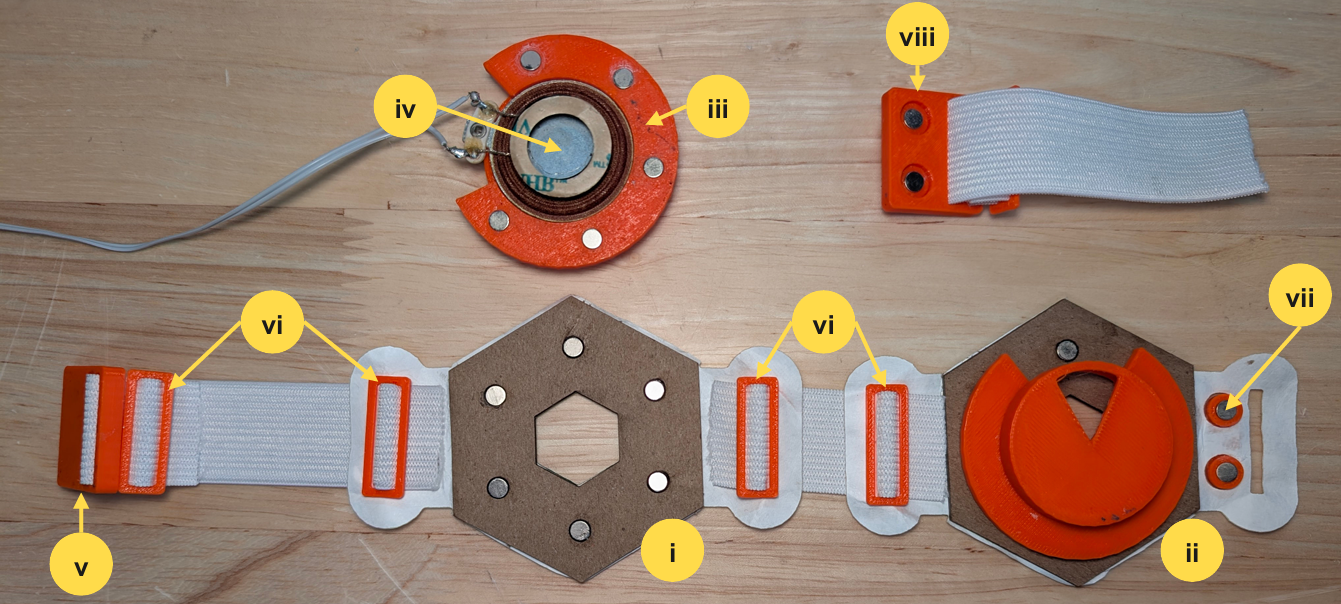

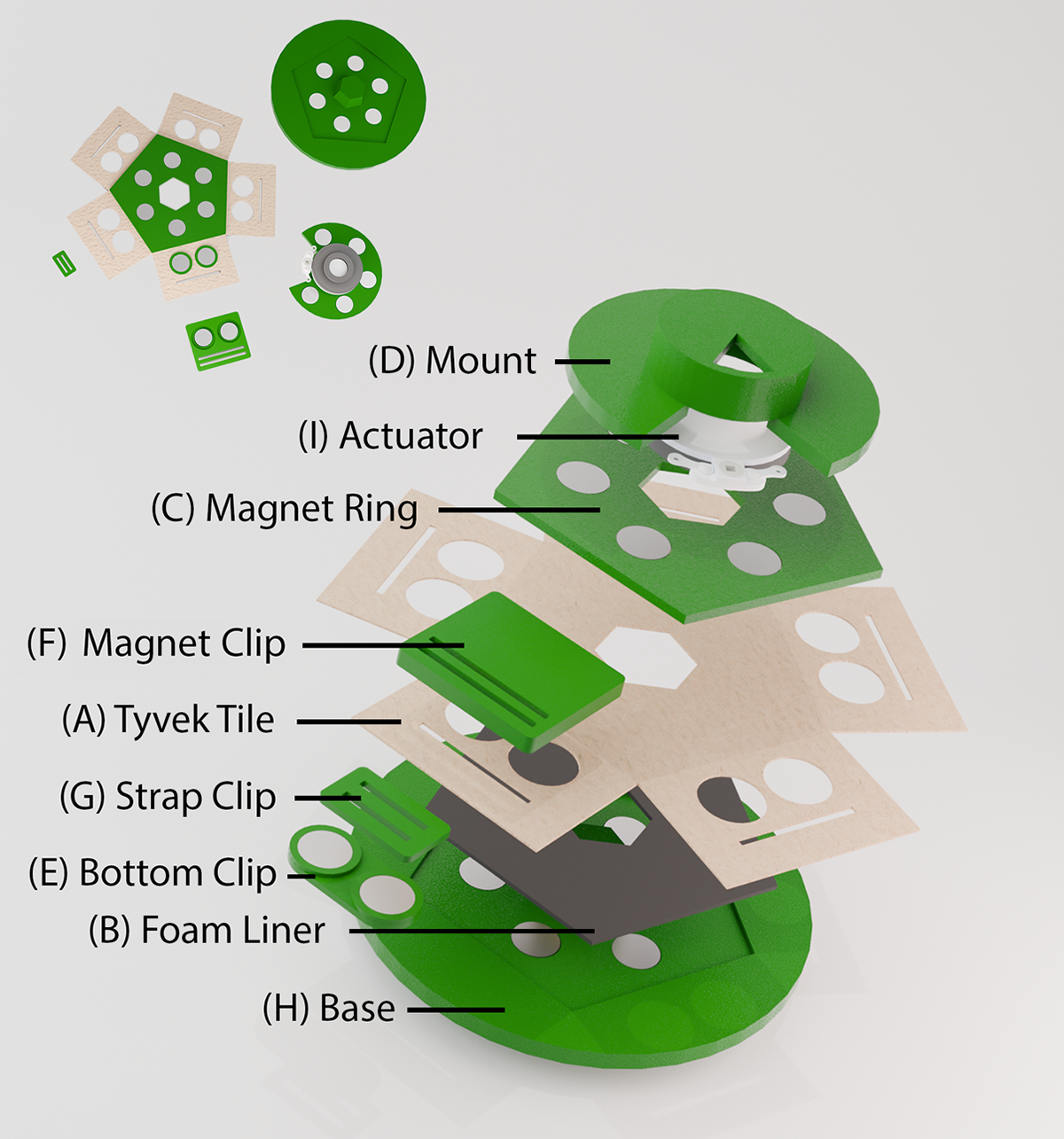

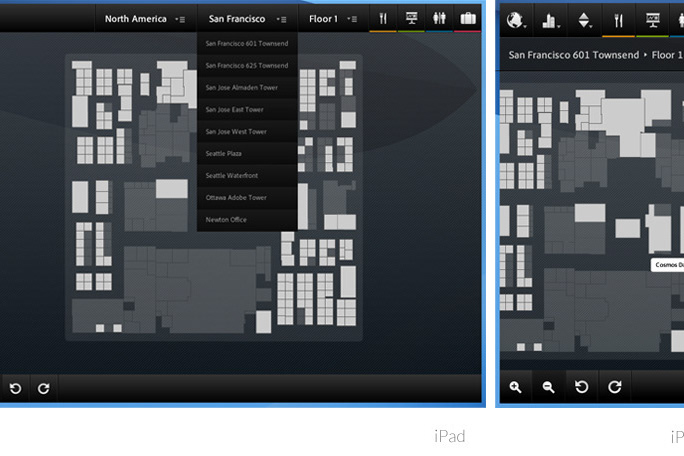

As the project lead, I focused on designing and validating a seamless, end-to-end hardware-software workflow. The hardware system was designed for modularity, reconfigurability, and cost-effectiveness, with a cost of only $15-$20 per-harness material. It combines 3D-printed parts, magnetic connectors, and accessible materials like Tyvek and EVA foam.

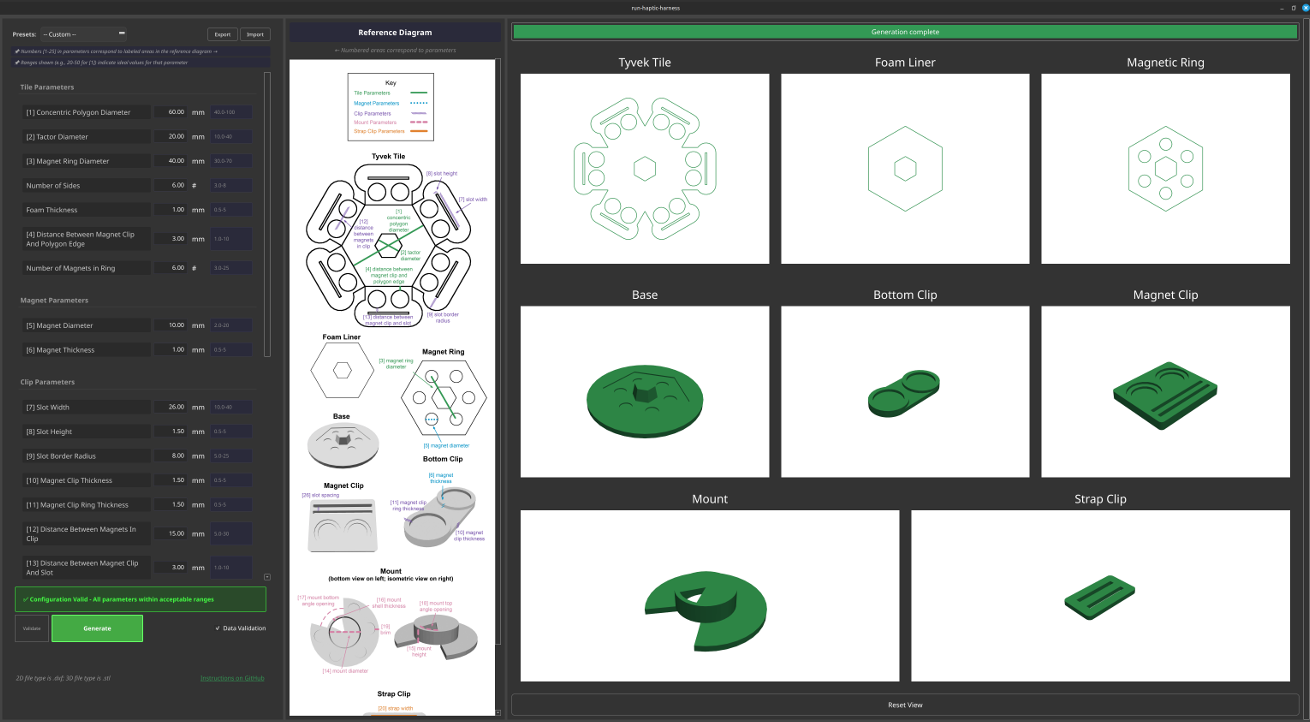

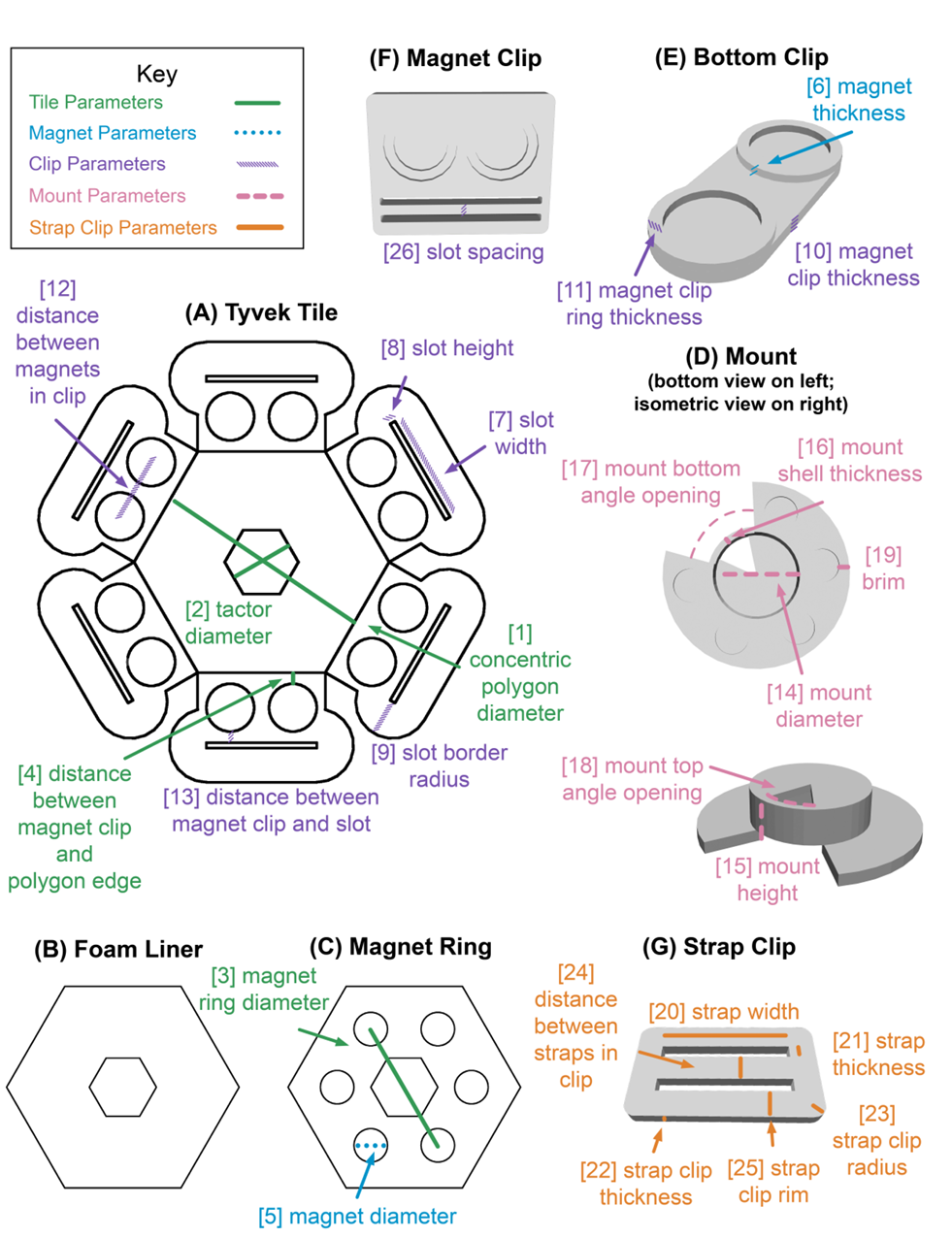

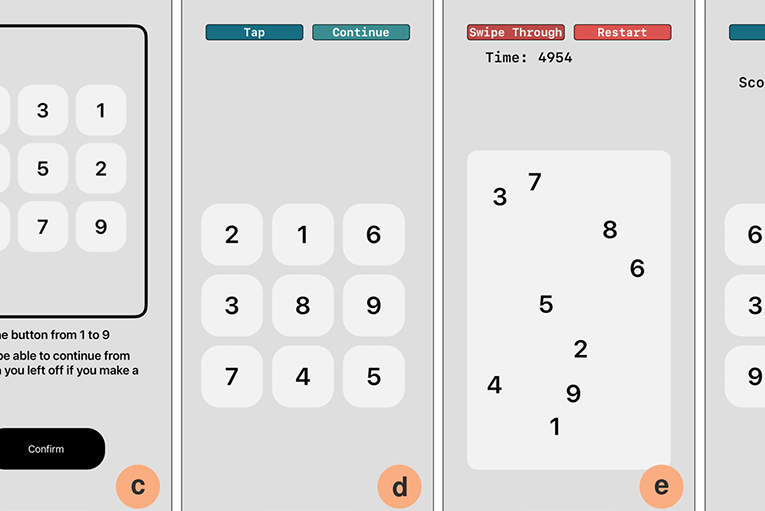

I architected the accompanying parametric design software as the core of this streamlined workflow. Instead of requiring users to learn traditional CAD, our software allows them to adjust key parameters (like tile size or actuator spacing) through an intuitive GUI. The system then automatically generates all the fabrication-ready files (.stl for 3D printing; .dxf and .svg for cutting). We followed a user-centered, iterative design process. We first conducted a usability study with 12 haptic researchers on the initial software, then used their direct feedback to develop an improved version 2 with better validation, error handling, and presets.

Challenges

The primary challenge was balancing comprehensive customization with ease of use. Our parametric software features 29 adjustable parameters, which offer excellent flexibility but could overwhelm novice users. Our initial usability study confirmed that researchers found configuring the complex relationships and dependencies between parameters challenging.

A significant software development effort was required to address this in version 2. We implemented more robust validation checks, explicit error messages with corrective suggestions, and preset configurations to simplify the process. Another key challenge was ensuring the fidelity of the design-to-fabrication pipeline. That guarantees the physical, assembled harness accurately reflects the spatial layout and actuator placement from the user's digital design.

Value Addition

This project successfully delivered and validated a complete, open-source toolkit that significantly "lowers the entry barrier" for haptic hardware development. Our three-part evaluation confirmed the system's effectiveness:

- The physical hardware received "good" usability (SUS median 72.5) in a workshop with 18 participants.

- The design software (v1) was rated "excellent" (SUS median 83.75) by 12 haptic researchers.

- The final end-to-end workflow validation (n=8) showed that researchers could create custom harnesses in an average of 26 minutes, with 87.5% reporting the process was faster than their traditional methods.

- The design software (v1) was rated "excellent" (SUS median 83.75) by 12 haptic researchers.

- The final end-to-end workflow validation (n=8) showed that researchers could create custom harnesses in an average of 26 minutes, with 87.5% reporting the process was faster than their traditional methods.

This project refined my skills across the full stack of Human-Computer Interaction (HCI) toolkit research: hardware prototyping, parametric software architecture, iterative UX design, and managing a rigorous, multi-stage user evaluation pipeline.

Links